When industrial equipment suddenly fails, production schedules can collapse within minutes. In these high-pressure situations, emergency machining services provide the speed and precision companies need to recover quickly. These services are designed to manufacture replacement or custom parts on extremely short timelines without sacrificing quality. By combining advanced CNC technology with experienced machinists, emergency machining helps industries avoid costly downtime and maintain operational stability.

This article explains how emergency machining services work, why they are essential for modern businesses, and how choosing the right provider can protect productivity and profits.

Understanding Emergency Machining Services

Emergency machining services focus on urgent production needs that cannot wait for standard lead times. Instead of following routine schedules, these services prioritize critical projects and deliver parts in hours or within a single day whenever possible.

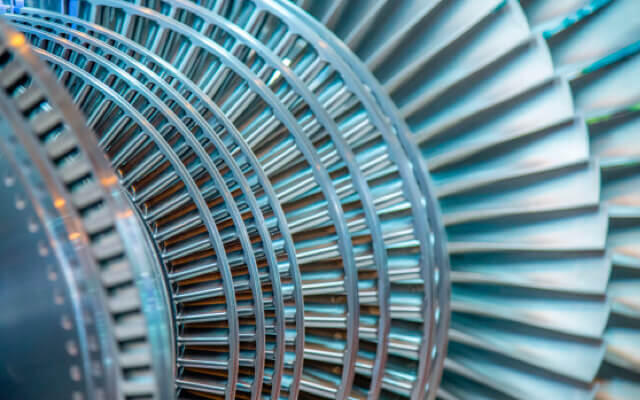

Most emergency machining providers use CNC milling, turning, drilling, and fabrication processes to create precise components. Accuracy is vital because replacement parts must fit perfectly into existing machines. Even under tight deadlines, quality inspections are performed to ensure that safety and performance standards are met.

Core Functions of Emergency Machining

The primary functions of emergency machining include rapid part reproduction, custom component manufacturing, and equipment repair support. These services are often available 24/7, allowing businesses to receive help at any time. Flexibility is another key function, as emergency jobs frequently involve unique or discontinued parts that are not available from original manufacturers.

Why Emergency Machining Is Critical for Businesses

Unexpected equipment breakdowns can affect entire supply chains. Manufacturing plants, processing facilities, and distribution centers depend on continuous operation to meet customer demand. When one part fails, production may stop completely. Emergency machining services reduce the impact of these failures by providing fast and dependable solutions.

Industries such as oil and gas, automotive, aerospace, and medical manufacturing rely on precise components that must operate safely and consistently. Delays in these sectors can result in safety risks, regulatory challenges, and financial losses. Emergency machining ensures that these industries can respond quickly and keep systems running smoothly.

Financial Advantages of Fast Machining

Although emergency machining may seem costly at first, it often saves money over time. The expense of halted production, idle labor, and delayed shipments can be far greater than the cost of urgent machining services. Fast turnaround helps companies protect revenue, maintain customer trust, and avoid long-term operational damage.

How an Emergency Machine Shop Supports Urgent Needs

An emergency machine shop is structured for speed, accuracy, and efficiency. These shops are equipped with advanced CNC machinery and staffed by skilled technicians who can analyze damaged parts and reproduce them quickly. Their workflows are streamlined to eliminate unnecessary delays and focus on rapid production.

Step-by-Step Emergency Machining Process

The process usually begins with reviewing the customer’s requirements. This may include studying CAD drawings, digital files, or physical samples of broken components. Machinists then select the best materials and machining methods to match original specifications.

Once production starts, inspections are performed throughout the process to ensure proper tolerances and quality. After completion, the part is delivered or made available for immediate pickup so installation can begin without delay. Clear communication during each stage helps customers stay informed and confident.

Industries That Depend on Emergency Machining

Emergency machining services support many industries that cannot afford long equipment downtime. Manufacturing plants rely on them for gears, shafts, and custom brackets. Energy and utility facilities depend on emergency machining for pumps, valves, and pressure system components.

The medical industry also benefits greatly from fast machining solutions. Equipment failures in hospitals and laboratories can affect patient care. Emergency machining ensures that replacement parts are produced quickly so essential systems remain operational.

Aerospace and defense industries require extreme precision and strict compliance with quality standards. Emergency machining providers help meet these requirements while still offering rapid turnaround times.

Practical Industry Example

Consider a packaging facility where a custom drive shaft breaks unexpectedly. Without this component, the entire production line stops. An emergency machining provider can recreate the shaft using CNC technology within hours, allowing operations to resume the same day and preventing costly delays.

Choosing the Right Emergency Machining Provider

Not every machine shop can handle urgent production demands. Businesses should look for providers with modern CNC equipment, experienced machinists, and a proven track record of fast turnaround. Certifications and strong quality control systems also indicate reliability and professionalism.

Location is another important factor. A nearby provider can reduce shipping time and ensure faster delivery. Shops that offer 24/7 service are especially valuable for companies that operate continuously or across multiple shifts.

Preparing for Unexpected Breakdowns

Preparation plays a major role in reducing downtime. Companies should keep digital design files of critical components and establish relationships with trusted emergency machining providers. This proactive strategy allows faster response when unexpected failures occur and helps maintain business continuity.

A Conversational Look at Emergency Machining Services

Let’s talk about emergency machining services in everyday language. Think of them as a backup plan for your machines. When something breaks, you do not have to wait weeks for a replacement part. Skilled machinists step in, produce exactly what you need, and help you get back to work quickly. This level of support gives businesses confidence and stability in unpredictable situations.

Conclusion

Emergency machining services are a vital solution for industries that cannot afford extended downtime. By delivering fast, precise, and dependable parts, these services help protect productivity and maintain business continuity. From manufacturing and energy to healthcare and aerospace, emergency machining ensures that equipment failures do not become long-term setbacks. Choosing a reliable provider and planning ahead allows businesses to stay resilient and prepared for any challenge.

Frequently Asked Questions

1. How quickly can emergency machining services produce parts?

Most emergency machining providers can deliver parts within the same day or within 24 hours, depending on part complexity and material availability.

2. Can emergency machining services handle custom or discontinued parts?

Yes, emergency machining services specialize in producing custom and hard-to-find components using advanced CNC technology and precise measurements.

3. What should businesses do to prepare for machining emergencies?

Businesses should store digital design files of key parts, partner with a reliable emergency machining provider, and plan for rapid response when equipment failures occur.